The Impact: Why Fuji Electric Is Well‑Positioned

Breadth of Portfolio: Fuji Electric is not just selling components (like semiconductors or drives), but systems + solutions. Their business spans from power generation to grid infrastructure, to automation, to power quality. Fuji Electric

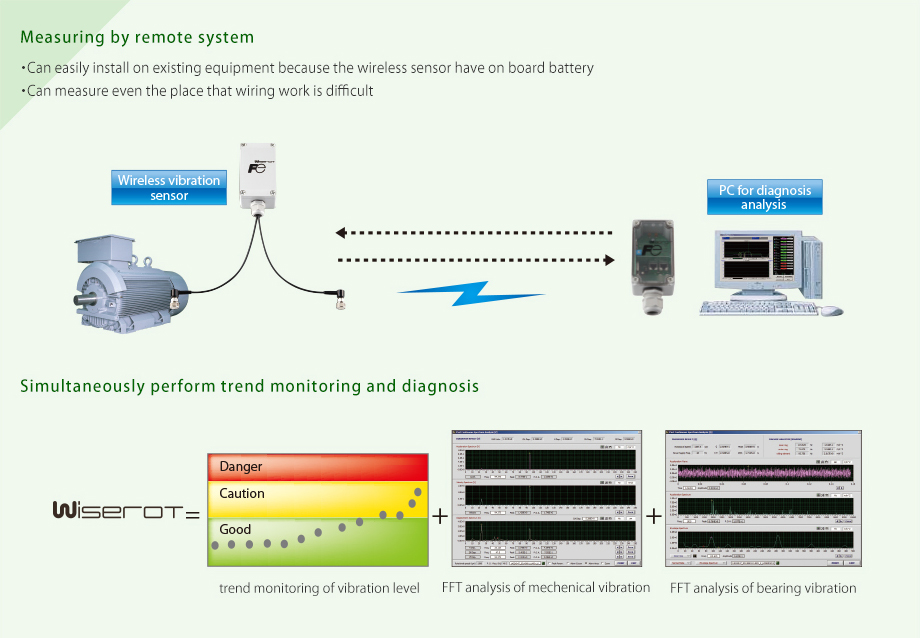

Digital Transformation: They integrate IoT, AI, and edge computing, turning legacy industrial systems into smart, data-driven operations.

Sustainability Alignment: Their technologies (e.g., heat-pump-based waste heat recovery, fuel cell) align with carbon‑neutral / decarbonization goals. felib.fujielectric.co.jp+1

Resilience: Through UPS, predictive maintenance, and remote support, they build resilient infrastructures that reduce downtime and risk.

Flexible Business Models: From VPP to remote monitoring, for both industrial and infrastructure clients, Fuji can tailor offerings to customer needs.